Eddy Current

Surface and subsurface non-destructive test method Testing

Eddy Current Testing

Eddy current inspection is extremely versatile, which is both an advantage and a disadvantage. The advantage is that the method can be applied to many inspection problems provided the physical requirements of the material are compatible with the inspection method. In many applications, however, the sensitivity of the method to the many properties and characteristics inherent within a material can be a disadvantage; some variables in a material that are not important in terms of material or part serviceability may cause instrument signals that mask critical variables or are mistakenly interpreted to be caused by critical variables

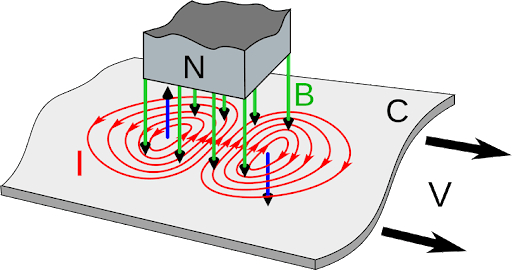

Physical Principle

In eddy current inspection, the eddy currents create their own electromagnetic field, which can be sensed either through the effects of the field on the primary exciting coil or by means of an independent sensor. In nonferromagnetic materials, the secondary electromagnetic field is derived exclusively from eddy currents. However, with ferromagnetic materials, additional magnetic effects occur that are usually of sufficient magnitude to overshadow the field effects caused by the induced eddy currents. Although undesirable, these additional magnetic effects result from the magnetic permeability of the material being inspected and can normally be eliminated by magnetizing the material to saturation in a static (direct current) magnetic field

Electrical Conductivity

All materials have a characteristic resistance to the flow of electricity. Those with the highest resistivity are classified as insulators, those having an intermediate resistivity are classified as semiconductors, and those having a low resistivity are classified as conductors. The conductors, which include most metals, are of greatest interest in eddy current inspection. The relative conductivity of the common metals and alloys varies over a wide range.

Capacity for conducting current can be measured in terms of either conductivity or resistivity. In eddy current inspection, frequent use is made of measurement based on the International Annealed Copper Standard. In this system, the conductivity of annealed, unalloyed copper is arbitrarily rated at 100%, and the conductivities of other metals and alloys are expressed as a percentage of this standard. Thus, the conductivity of unalloyed aluminum is rated 61% IACS, or 61% that of unalloyed copper.